Hydraulic valves. Intended for use in potentially explosive atmospheres

In segments of the chemical and petrochemical industries or mines, hazardous explosive mixtures appear in the form of gas, vapor, mist or dust. A high level of protection against explosions must be ensured in every part of the mechanical or electrical equipment used in these potentially explosive areas. For applications in such areas, ARGO-HYTOS offers a wide range of screw-in and modular cartridge directional valves.

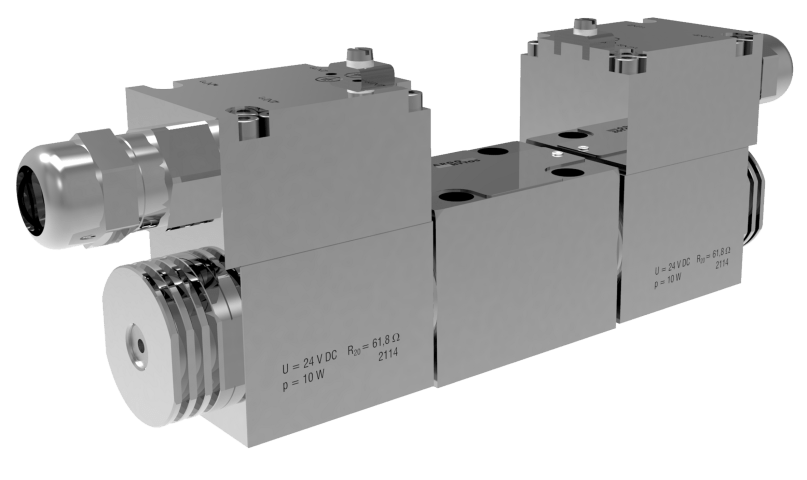

When using solenoid-operated hydraulic valves, a common method is to avoid the accumulation of energy, which would be sufficient for the ignition of an explosive mixture. The hottest part of the valve is usually the solenoid.

Solenoid system

The new ARGO-HYTOS One4All Explosion Proof Solenoids are designed for use in all explosion hazard areas and temperature classes in combination with modern design methods, resulting in unique hydraulic power performance.

The new ARGO-HYTOS One4All Explosion Proof Solenoids are designed for use in all explosion hazard areas and temperature classes in combination with modern design methods, resulting in unique hydraulic power performance.

ARGO-HYTOS uses two types of protection in the electrical parts of our valves: “Ex e” type – greater safety for the connection terminal in DC coils and “Ex mb” type – encapsulation in our AC coils with a rectifier bridge .

The hydraulic power transmitted by valves designed for explosive environments is typically less than the power of conventional valves. ARGO-HYTOS, which has been in valve and solenoid development for over 60 years, has achieved extraordinary high-flow and pressure parameters thanks to modern development methods in the new family of explosion-proof screw-in and modular directional valves. One of the key elements is the explosion proof solenoid.

Design

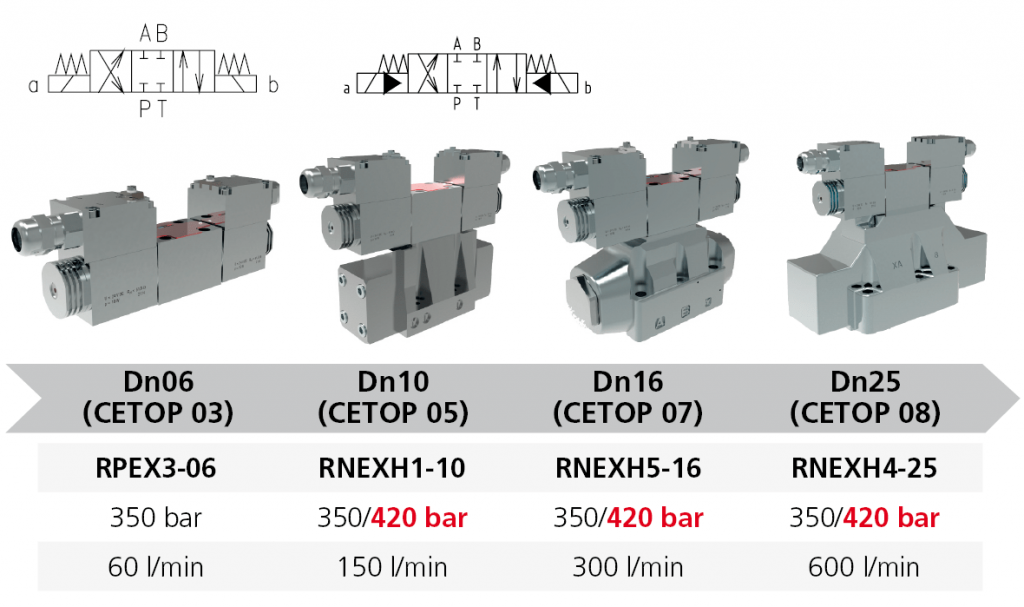

- Modular valves available in four sizes: 06 (D03), 10 (D05), 16 (D07), 25 (D08) ISO 4401

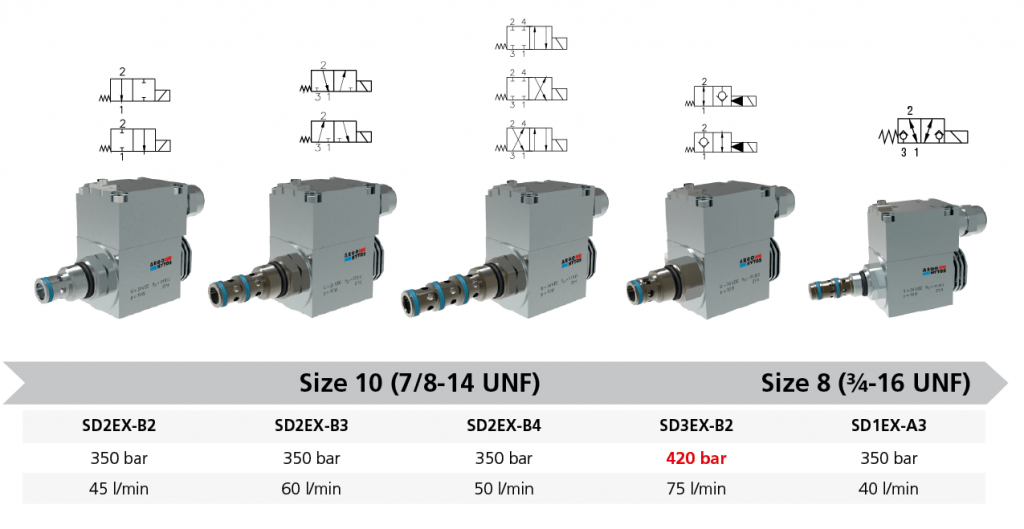

- Screw-in cartridges with check valve and spool in sizes 08 and 10

- Special manual bayonet override for all easy emergency changes ›Unique detent function on modular directional valves

- Meets shock and vibration demands Advantages and Benefits ›One4All solenoid system for all T4 / 5/6 classes and all areas such as mining / gas / oil + dust› Solenoids are interchangeable between the modular cartridge range and screw-on

- Extraordinary high transmission hydraulic power ›Constant performance in different working conditions› CETOP + SIC valve range robust design for 10 million life cycles

- Screw-in cartridge seat valves with 0 drop leakage and nominal pressure 420 bar

- Cartridge spool valves equipped with a swivel nose feature to compensate for cavity misalignments

- High oil / ambient temperature as standard ›Suitable terminal box for simple and safe cable installation

- Improved surface protection 520h acc. according to DIN 9227